HOME >> News >> Company News

Managed Pressure Drilling(MPD) Corperations |

[ Time:2019-01-03 | Hits:5315 ] |

Changyou and partner developed MPD package which has served several jobs successfully at oilfield site.

MANAGED PRESSURE DRILLING EQUIPMENTS AND SYSTEM MANUFACTURER IN CHINA

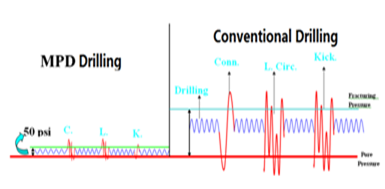

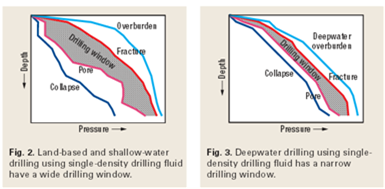

Brief intros: On land and in some shallow water environments, a comfortable drilling window often exists between the pore-pressure and fracture-pressure gradient profiles, through which the hole can be drilled safely and efficiently, Fig.2. From an offshore prospective, MPD was and still is driven by the very narrow margins between formation pore pressure and formation fracture pressure downhole. Narrow margins are most pronounced in deepwater drilling, where much of the overburden is seawater, Fig.3. In such cases, it is standard practice to set nu-merous casing strings at shallow depths to avoid extensive lost circulation.

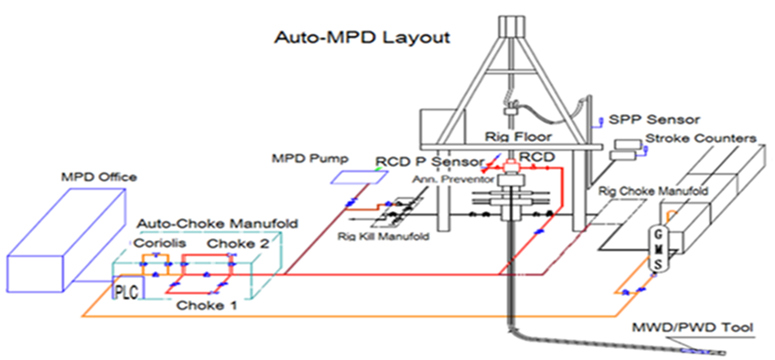

Product Functions: Various control modes, and adapts to the needs of different drilling technologies; Meets the needs of drilling technology of low density window, and achieves precise control of well pressure;Intelligent identification and automatic control functions, and can optimize the selection of calculation model which combined with well logging data on site; Intelligent error diagnosis and manual intervention reminding, which increases safety and reliability of drilling and production. Performance Features: Proportional control technology and has precise control of system pressure;Featured by closed loop monitoring with annulus pressure, multiple strategies, and self-adaption; The control system uses redundant industrial Ethernet with 100M high-speed data transmission rate; Without adjusting the drilling fluid density, it can quickly respond to changes in reservoir pressure, protect the reservoir, and reduce the damage; By reducing drilling pressure, improving drilling speed and reducing number of casing layers, it can reduce drilling costs.

Associated with conventional drilling technologies. Does not invite influx but is equipped to contain any that might be incidental to the operation. Does use underbalanced equipment to more precisely manage the pressure profile throughout the wellbore. MPD can be used in conventional oil and gas applications, although it also has unique applications to coal bed methane, geothermal resources and drilling for commercial quantities of methane hydrates.

(MPD)forage précisément réussi de pression système collecteur se

compose essentiellement de système de contrôle de pression -, système de

compensation, système de surveillance à distance et de logiciel, etc.

(application des règles et normes: api spec 6a, api spec 16c, api spec

16rcd).le système est caractérisé par l'intégration des fonctions de

surveillance et de contrôle de pression micro flux.logiciels de contrôle

automatique grâce à la recherche et au développement indépendant, il

permet un contrôle précis de la pression de fond et atteindre délicate

forage géré la pression.

Precisamente logró perforar (MPD) presión sistema consiste

principalmente de choke Manifold sistema de control, presión trasera

sistema de compensación, sistema de monitoreo remoto y sistema de

software, etc. (la aplicación de las reglas y normas: API Spec 6a, API

SPEC 16C, API Spec 16rcd).El sistema se caracteriza por la integración

de las funciones de supervisión y de control de la presión de flujo de

micro.Mediante el software de control automático en la investigación

independiente y el desarrollo, que permite un control preciso de la

presion de fondo de pozo de perforación y lograr la delicada presión

gestionados.

الدقة في إدارة الحفر تحت الضغط MPD ويتألف النظام أساسا من نظم التحكم في تحويل مجرى المياه، ونظم تعويض الظهر، ونظم المراقبة عن بعد، ونظم البرمجيات (معايير وقواعد التنفيذ: API Spec 6A، API Spec 16C، API Spec 16RCD) ويدمج النظام وظائف رصد الإجهاد ورصد الدفق المتناهي الصغر .وتحقق التحكم الدقيق في ضغط قاع البئر من خلال برامجيات التحكم الآلية التي طورت بصورة مستقلة، وحفرت آبار دقيقة لإدارة الإجهاد.

|